Field coating / top coating

To ensure that plastic coated pipes have the necessary load-bearing strength, they should be field coated with a three-layer system (heat-shrink tubes or collars with an additional epoxy resin primer) or a duromer system (polyurethane or GFR laminates). Alternatively, a coating system compliant with DIN 30672 or DIN EN 12068 can be combined with a GFR coating. The field coating should be flush with the mill-applied coating.

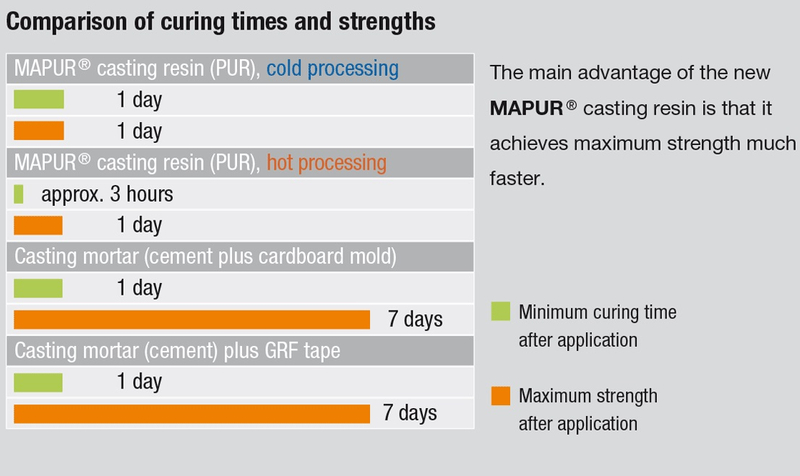

The joint areas of FCM coated pipes are field coated as usual with field coating material conforming to DIN 30672 or DIN EN 12068. Casting mortar (see "FCM coating") is used for mechanical protection. Where stresses are very high or time is at a premium (MFR coatings usually need at least 24 hours to set), an alternative or additional coating is also available here, namely with GFR material or polyurethane tapes. This raises the mechanical load-bearing strength and allows the setting time to be correspondingly shortened.

FCM coated pipes are not suitable for trenchless pipe-laying with a driving technique (e.g. pipe ramming or thrust boring) since this could destroy the adhesive bond between the plastic coating and the FCM top coat.

FCM coatings have a coarser surface than plastic coatings and they are hygroscopic. If required, the top coat can be pre-treated to reduce friction on the pipe surface before it is drawn in.

With FCM top coats, just as with plastic coatings, the transition area between the mill- and the field-applied coatings must be as even as possible without any great cross-sectional variations. So careful application of the field coating systems is very important.

Coating systems that provide exactly the required level of mechanical protection are available for every application profile. It is therefore possible and essential, especially in trenchless projects, to rule out excessive loads on the coating, e.g. when drawing in a pipe string on a roller system. The use of point supports for complete string sections is impermissible.

The coating products MAPUR® and MAPUR2012® were developed specifically for the new systems used in trenchless pipe-laying (e.g. FZM-S or multi-layer coating systems). Supporting the systems approach, they provide optimum protection in demanding pipeline construction projects.

For our systems approach (steel pipe with mill-applied coating and suitable field coating of the joint areas), we cooperate with Schneider & Co. Protec Service (http://www.schneider-co.eu/).