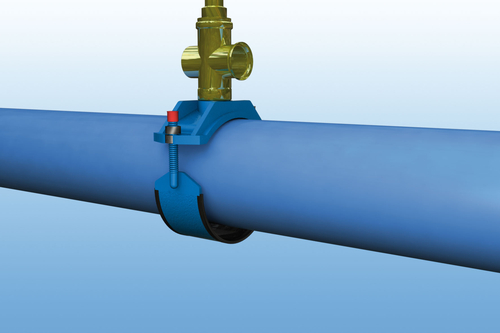

Saddle fittings

To fix a saddle fitting to a polyethylene coated pipeline, the polyethylene does not have to be removed at the site of the fitting. The additional FCM coating provides mechanical protection. Unless special tapping devices and saddle fittings are used, the FCM has to be removed before tapping.

The saddle fitting carrier bracket must be designed to avoid any damage to the corrosion protection system. A wide mounting piece exerts less pressure on the pipe surface.

Spiral drills made of tool steel or super high-speed steel, or carbide-tipped cutters are suitable for avoiding long chips. Tool steel, super high-speed steel or diamond-tipped bits are also suitable. All drill attachments must be suitable for drilling steel pipes (see manufacturer’s specifications).

The tapping tool must allow the drill or milling cutter to be advanced slowly to avoid damaging the cement mortar lining.