Pipe trench and bedding

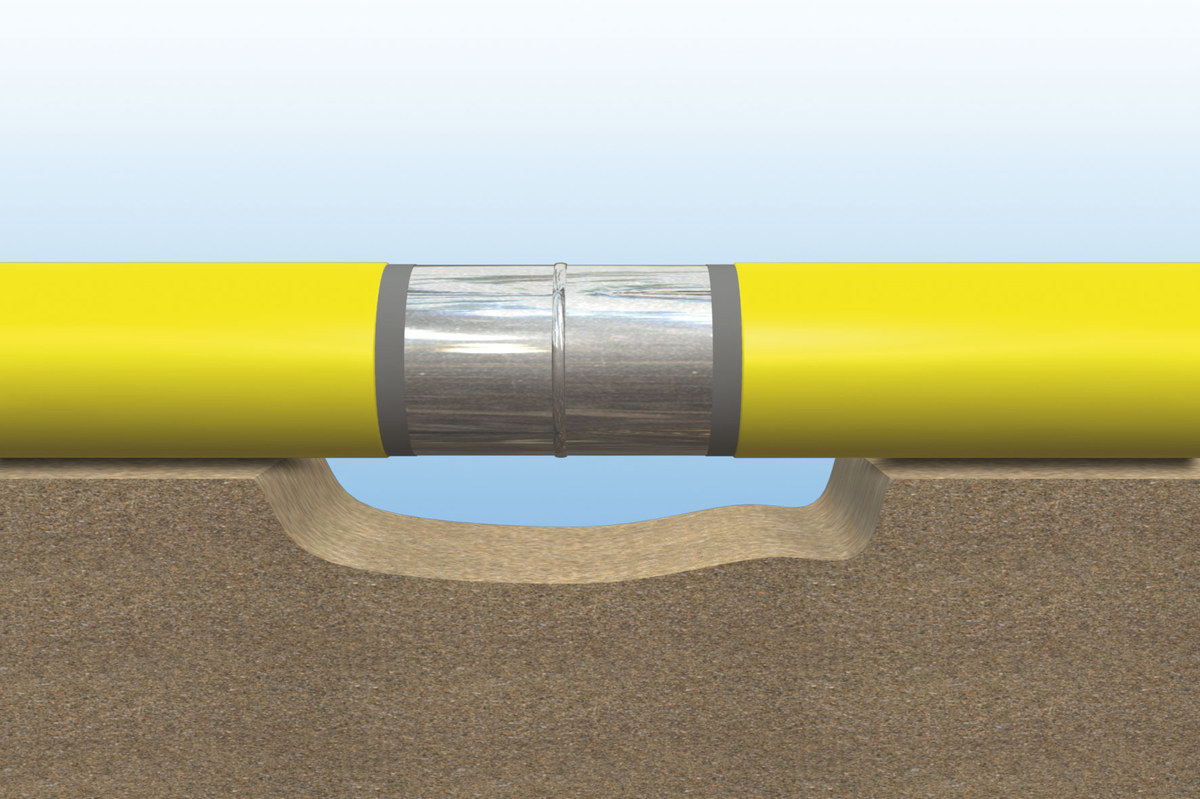

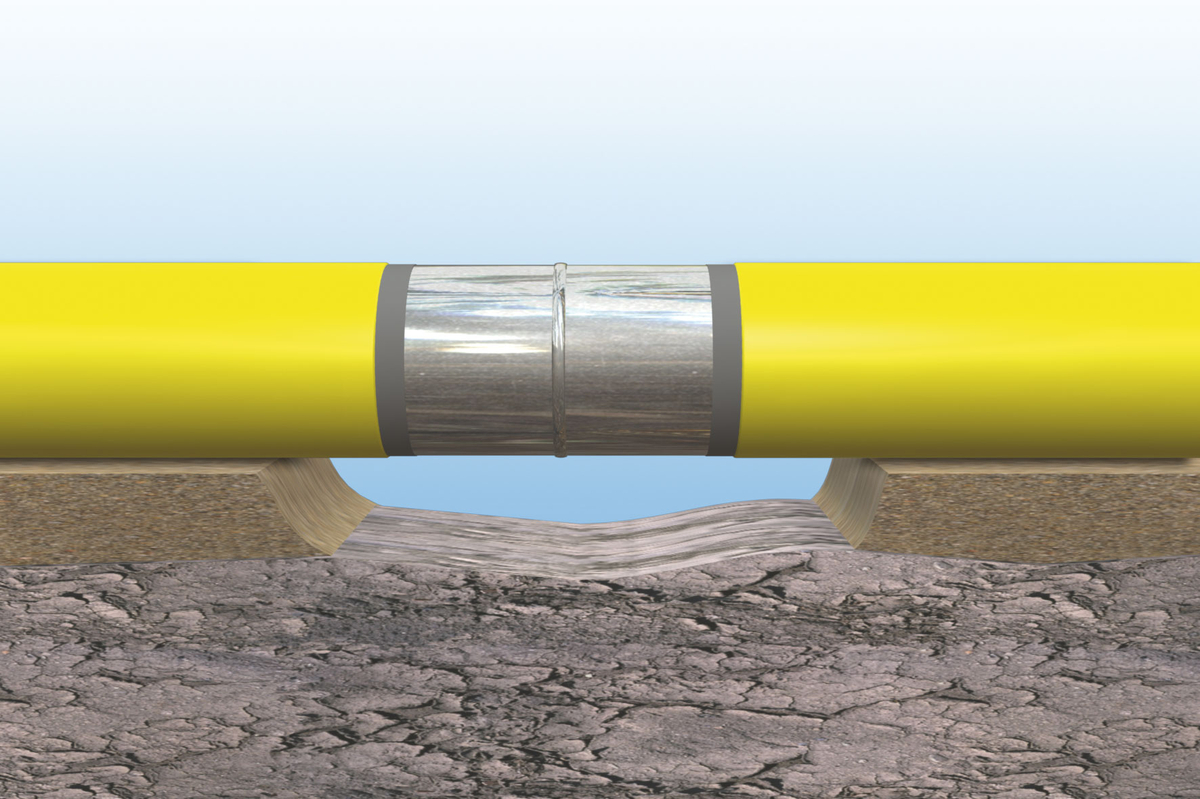

Steel pipes with welded joints can be laid individually or as a prewelded string. Before the pipes are lowered, a solid, uniform bearing must be ensured in the bottom of the trench along the entire length of the pipeline. Point supports must not be used, due to the resulting uneven pressure distribution. Joint holes must be prepared in such a manner the joints can be properly made up and tested:

Usually the excavated spoil is a suitable support. If the pipes are plastic coated, they must not be laid directly on stony ground or rock. In such cases the pipe trench must be dug deeper so that a layer of suitable stone-free compactable material can be added. If the trench as dug is not suitable for bearing loads, other safety measures may have to be taken.

Polyethylene- and polypropylene pipes is shown in the PDF file which you can download below coated pipes must be bedded in stone-free material. Suitably deep layers of sand, gravelly sand, sieved soil or other suitable materials can be used for this purpose and compacted if necessary. Depending on the laying conditions and the bedding material, the following particle sizes are recommended:

| Pipe-laying with compaction | Pipe-laying without compaction | ||

|

Round grain (sand/gravel) |

Crushed grain (stone/shingle) |

Round grain (sand/gravel) |

Crushed grain (stone/shingle) |

|

0 to 4 mm max. 8 mm |

0 to 5 mm max. 8 mm |

0 to 8 mm max. 16 mm |

0 to 5 mm max. 8 mm |

The bedding materials and grading curves specified above are recommendations in accordance with the listed standards. Other bedding materials with comparable properties or proven suitability for use in the given conditions can also be used.

For steel pipes with a polyethylene coating and additional FCM top coating, the excavated material can be used to backfill the trench. If compacting is specified, the material must be compactable and the cover height must be at least three times the size of the largest grain in the backfill material.